Since the development in the 1990s, the processing methods of non-woven medical protective materials have been relatively mature. According to their different preparation techniques, there are currently several types of spunbond, melt-blown, SMS composite technology, spunlace and flash evaporation.

These five preparation techniques each have their own strengths. Xiao Bian introduces you to each of them individually.

Spunbonded nonwovens

The strength and comfort of spunbond nonwovens can meet the basic requirements of medical protective materials, but they are relatively weak in barrier properties and do not meet the standards of medical protective materials. To solve this problem, fine denier spunbond technology has become a research hotspot.

Germany's Freudenberg company first invented bicomponent spunbonded spunlace technology, the use of hollow segmented spinning components, after the melt stream is extruded from the orifice, after cooling blow, air draft to form a filament shop Placed in a net curtain, and then using high-pressure hydroentangling technology for fiber opening and fixed network, compared with ordinary spunbonded or spunlaced non-woven material, its relatively good barrier properties, it can be used for medical protective materials.

Meltblown non-woven technology

The most prominent feature of meltblown non-woven technology is that the fibers are very fine. After being bonded by themselves, the structure is bulky, the porosity is high, the average pore size is small, and the barrier properties are very good. However, the strength and wear resistance of the products need to be improved.

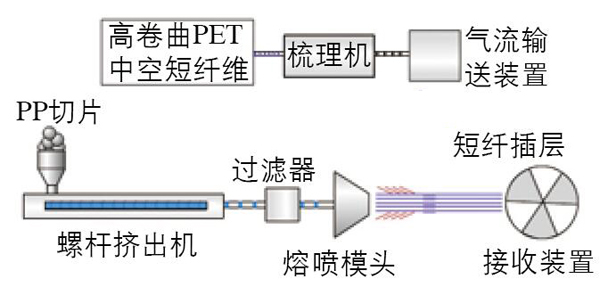

Considering the problem of fine meltblown fibers and poor compression resilience, U.S. 3M took the lead in the development of an intercalation melt-blown process, which injects high-denier, high-curl, meltblown fibers into the meltblown fiber stream during the traditional meltblown production process. Hollow elastic staple fiber, under the same grammage, the compression resilience of the product is greatly improved, and the structure becomes more bulky, and the air permeability and moisture permeability are also improved; moreover, the distance traveled by the particles in the material is longer and the distance is longer. Increased the interception effect, so that the barrier effect on the particles is greatly improved.

SMS composite technology

In view of the poor barrier properties of spunbonded nonwovens and the low strength of meltblown nonwovens, the strength and abrasion resistance of spunbonded fabrics was used as the surface layer, and the barrier properties of meltblown fabrics were used as the core layer. SMS composite nonwovens were prepared.

In view of the fact that most SMS composite protective materials use PP as raw material and have poor protective performance against various radioactive materials, Liu Xing and others from Tianjin Polytechnic University have cooperated with a certain navy department to coat the SMS material with barium sulphate. It can prevent the penetration of radioactive substances, so it can be used by medical personnel to avoid unnecessary radioactive interference, cause lesions, and play a better role in isolation protection. The coating material can also be made into a sustained-release microcapsule shape for coating. When subjected to an external force, the microcapsules are broken and the protective performance is enhanced.

Spunlace Non-woven Technology

For non-woven materials with short fibers that have been carded and then hydroentangled and fixed, they have great advantages in terms of softness, breathability, and breathability, but due to their poor barrier properties, they can only be used as general medical materials. Protective performance is not very good.

In 2009, the University of Leeds in the UK developed a type of functional spunlace non-woven material that uses a special device to form a hole structure in the spunlace nonwoven during the spunlace process. Sustained release antiseptic capsules can be added.

This type of spunlaced non-woven material with micro-capsules for sustained release of disinfectants can be used as a cross-infection protective material placed in the door handles, handrails, etc. in hospitals that come in contact with the human body. When a person pushes the door or closes the door, he is sick. The patient will pass germs through the hands to the contact handles. At this time, the microcapsules will release the disinfectant under the pressure of the hand and effectively kill the germs. Other patients or healthy people will not be infected again by touching the handles. This type of anti-cross-infecting non-woven protective material has been applied in some hospitals in the UK, and the effect is very good.

Flash Nonwoven Technology

Compared to SMS, the flash evaporation technology uses the solution spinning method to form a solvent, which is a volatile organic solvent, which is difficult to recover. The high concentration in the air can easily cause an explosion accident. In addition, during the production process, fiber spinning Speed control is very difficult.

Currently, the technology is monopolized by DuPont, a US company. The protective clothing made by Tyvek, a flash evaporation product, combines protection, durability, and comfort to protect workers from micron-sized particles, but at a relatively low cost. Higher.

As more and more stringent requirements have been placed on protective materials, the preparation of these non-woven protective materials is also progressing towards versatility, high performance and differentiation. It is believed that with the continuous promotion of science and technology, new preparation technologies will come into being, and the defects of non-woven medical materials will become less and less.

Yancheng Ruize Masterbatch Co., Ltd. mainly produces and operates: Non-woven masterbatch, Non-woven antibacterial masterbatch,antistatic masterbatch, polypropylene filament masterbatch, Polypropylene filament masterbatch, Non-woven masterbatch, polypropylene spunbond non-woven masterbatch, Polypropylene fiber masterbatch, chemical masterbatch, Non-woven masterbatch, polypropylene masterbatch, Soft hydrophilic masterbatch.

- Mizlion made a stunning appearan

- Why is it said that polypropylen

- The impact of the Federal Reserv

- Chemical fibers "carry static el

- What are the core considerations

- The High Performance and High Fu

- At the end of the year, a new ch

- Exhibition Invitation: Ruize Mas

- Ruize Masterbatch congratulates