Flame-retardant fabric refers to reducing the flammability of the material in the flame and slowing down the flame spread speed. When the flame is removed, the material can self-extinguish quickly and reduce combustion. So, do you know which kinds of flame retardant fabrics are common on the market?

According to the flame retardant can be divided into the following three categories:

1. Non-permanent flame retardant: generally not washable, its composition is mainly salt. Such as ammonium borate, borax, ammonium phosphate, ammonium bromide, ammonium chloride and the like. Can be used alone or in combination.

2. Semi-permanent flame retardant: generally resistant to l-15 times warm water wash. Such as urea monophosphate (1:4), chloroammonium phosphate, PClS-pyridine, dicyandiamide-THPC (2:1) and the like.

3. Permanent flame retardant: generally more than 50 times washable, such as THPC, Pyrovatexcp, Flo 76 MCCIOOMCC200 and so on.

Among them, the use advantages of the flame retardant masterbatch are significant:

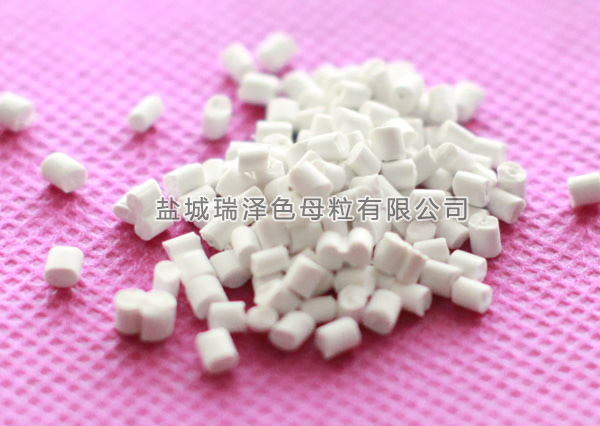

1. Easy to use: Most of the flame retardant masterbatch (masterbatch) is flaky or strip-shaped granules, which is just the same size as ordinary plastic granules, which improves the mutual compatibility between them, making it easier to disperse and add and be hygienic. And reduce the waste of evaporation.

2. Good compatibility with resin: Under normal circumstances, the flame retardant masterbatch has been specially treated to improve its compatibility with plastic resin, so that it is not easy to cause delamination even if it is added in the resin. , blooming, pattern and other issues.

3. Reduce costs and increase the added value of products: often the addition of flame-retardant masterbatch makes the general plastics have or close to the application requirements of engineering plastics, which increases the added value of products and reduces the cost of raw materials.

According to the fabric composition, it can be divided into the following four categories:

1. Elastic flame retardant fabric - This fabric is blended with 95% cotton fiber and 5% spandex fiber. In addition to the excellent properties of cotton fibers, it is more elastic and has better wrinkle resistance after being made into clothes.

2. Cotton flame-retardant fabric - the fabric is composed of 100% natural fiber "cotton", which has the characteristics of cotton fiber, breathable and moisture-permeable, comfortable to wear and soft to the touch. Available in a variety of sizes including twill, plain, satin and weft knitted fabrics.

3. C/N flame retardant fabric - the fabric is blended with 88% cotton fiber and 12% nylon fiber. It has good wear resistance, better strength and softer hand feeling. Its wearing life can be extended by more than 50%, which can better prevent electric sparks, electric arcs, metal droplets and so on.

4. CVC flame retardant fabric - the fabric has more than 60% cotton fiber, 40% or less of polyester fiber blended. It has the excellent characteristics of both cotton and polyester fibers, and has the characteristics of strong strength, good wear resistance and wrinkle resistance.

Ruize focuses on the development and production of high-quality flame retardant masterbatch, which can be used in the plastics industry and chemical fiber field. Welcome to buy! Choose Ruize, colorful!

Yancheng Ruize Masterbatch Co., Ltd. mainly produces and operates: Non-woven masterbatch, Non-woven antibacterial masterbatch,antistatic masterbatch, polypropylene filament masterbatch, Polypropylene filament masterbatch, Non-woven masterbatch, polypropylene spunbond non-woven masterbatch, Polypropylene fiber masterbatch, chemical masterbatch, Non-woven masterbatch, polypropylene masterbatch, Soft hydrophilic masterbatch.

- Mizlion made a stunning appearan

- Why is it said that polypropylen

- The impact of the Federal Reserv

- Chemical fibers "carry static el

- What are the core considerations

- The High Performance and High Fu

- At the end of the year, a new ch

- Exhibition Invitation: Ruize Mas

- Ruize Masterbatch congratulates