China produces about 20 million tons of waste textiles every year in the production and consumption sectors, but its comprehensive utilization rate is only about 15%.

According to estimates, if the comprehensive utilization rate of waste textiles in China reaches 60%, the annual output of chemical fiber is 9.4 million tons, and natural fiber is about 4.7 million tons, which is equivalent to saving 15.2 million tons of crude oil and saving 13.6 million mu of cultivated land, which will effectively alleviate the textile industry. Resource shortage.

The recycling of waste textiles is an inevitable path that meets the requirements of ecology, green, low carbon and environmental friendliness, and has received more and more attention.

For example, recycled waste cotton fabric is the raw material for producing regenerated cellulose fibers. The regenerated cellulose fiber currently produced is mainly viscose, which is made by dissolving cellulose into a spinning dope after being subjected to chemical alkalization, aging, yellowing and the like, and is formed by wet spinning. However, this method produces highly toxic by-products.

The only commercial alternative currently available is the solvent process for the production of Lyocell fibers. The chemical raw materials used in this method are non-toxic, but the ionic liquid has high cost and high viscosity, which causes certain difficulties in the production process.

In order to reduce the amount of ionic liquid, Nolene Byrne et al. of Deakin University in Australia proposed the use of dimethyl sulfoxide (DMSO) as a co-solvent and ionic liquid 1-butyl-3-methylimidazolium acetate ([Bmim]OAc). Together with the dissolution of waste cotton fabrics, the production process of regenerated cellulose fibers is improved. DMSO reduced the viscosity of the solvent for spinning and reduced its cost by 77%.

Moreover, this process preserves the color of the original fabric on the regenerated cellulose fibers as needed to avoid re-staining; the dye can also be removed to give the fibers a more common white color.

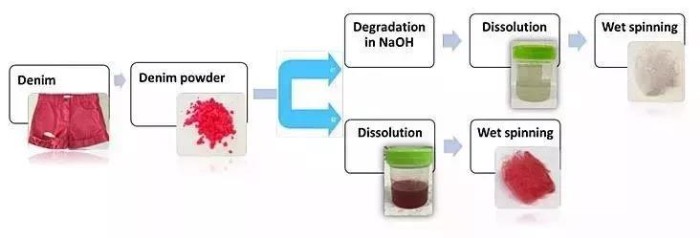

After completing the study of the solubility of the spinning solution and the rheology of the stock solution, the team began to recycle the waste cotton clothing into fibers. They chose a pair of red denim shorts, shredded and ground into a powder, and then the powder was placed in a 10% NaOH solution for agitation.

After 5 h of treatment with NaOH solution, the powder turned from red to white. If the trousers are not shredded and ground into a powder, they will not fade after treatment with NaOH solution. The red and white powders were each dissolved in a two-component solvent having a B/D of 20:80, and wet-spun to form red and white fibers, respectively.

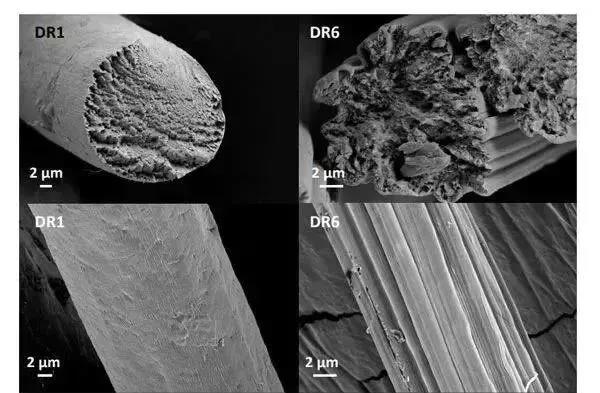

The white powder solution has a slightly higher whiteness than the white fiber because the ionic liquid itself is slightly yellowish. The red fiber has a lower color strength (K/S value) than the red shorts, indicating partial fading of the dissolution and wet spinning processes. Compared with viscose fiber, white fiber exhibits better overall mechanical properties and can meet the requirements of making garments.

The research team used a two-component solvent solution with a ionic liquid ratio of only 20%. Compared with the spinning solution made of pure ionic liquid as a solvent, the viscosity is reduced and the cost is reduced by 900 USD/kg. To $202/kg. The two-component solvent can be recycled and reused after distillation to achieve recycling.

This study provides an inexpensive and easy way to recycle sustainable cotton.

Yancheng Ruize Masterbatch Co., Ltd. mainly produces and operates: Polyester masterbatch, Non-woven masterbatch, Non-woven antibacterial masterbatch,antistatic masterbatch, polypropylene filament masterbatch, Polypropylene filament masterbatch, Polyester masterbatch, polypropylene spunbond non-woven masterbatch, Polypropylene fiber masterbatch, chemical masterbatch, polypropylene masterbatch, Polyester masterbatch, Soft hydrophilic masterbatch.

- Mizlion made a stunning appearan

- Why is it said that polypropylen

- The impact of the Federal Reserv

- Chemical fibers "carry static el

- What are the core considerations

- The High Performance and High Fu

- At the end of the year, a new ch

- Exhibition Invitation: Ruize Mas

- Ruize Masterbatch congratulates